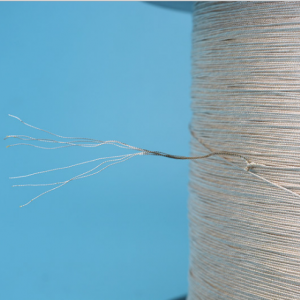

It’s nickel chromium ultra-high strength conductive/heating wire. its’ more flexibility and long working life than other wires, as the aramid / carbon yarn inside can bears the vertical tensile strength.

Advantages:

1.Heat-resistant, special for heating

2.High tensile strength,

3. Bending resistance. Not easy to break

4. Good corrosion resistance and high reliability

5. Low resistance and conductivity

Conductor materials available:

Nickel chromium, copper, tin-plated, silver-plated, gold-plated,nickel-plated,bare copper alloy, tin copper alloy , silver copper alloy etc. All wire can be designed and customized according to customers’ request of performance, technical Parameters, outer diameter etc.

Outer diameter range: 0.05mm-0.40mm.

Extruion(insulation coating) available,material can be PVC.Teflon etc according to your specify.

Stranding available.

Regualer specification

|

Outer Conductor |

Textile Inner Core |

Diameter mm |

Conductivity ≤Ω/m |

Weight m/KG |

Elongation≥% |

Strength ≥KG |

|

Copper 0.08mm |

250D Poyester |

0.20±0.02 |

6.50 |

9000±150 |

8 |

1.50 |

|

Copper 0.10mm |

250D Polyester |

0.23±0.02 |

3.90 |

7000±200 |

10 |

1.50 |

|

Copper 0.05mm |

50D Kuraray |

0.10±0.02 |

12.30 |

28000±1500 |

3 |

0.70 |

|

Copper 0.1mm |

200D Dinima |

0.22±0.02 |

4.00 |

7000±200 |

5 |

4.00 |

|

Copper 0.1mm |

250D Polyester |

1*2/0.28 |

2.00 |

5300±500 |

8 |

1.50 |

|

Copper 0.1mm |

200D Kevlar |

0.22±0.02 |

4.00 |

7300±200 |

5 |

3.80 |

|

Copper 0.05mm |

50D Polyester |

1*2/0.13 |

8.50 |

28000±1500 |

5 |

0.35 |

|

Copper 0.05mm |

70D Polyester |

0.11±0.02 |

12.50 |

21500±1500 |

5 |

0.45 |

|

Copper 0.55mm |

70D Polyester |

0.12±0.02 |

12.30 |

21000±1500 |

5 |

0.45 |

|

Copper 0.10mm |

Cotton 42S/2 |

0.27±0.03 |

4.20 |

6300±200 |

7 |

1.10 |

|

Copper 0.09mm |

150D Polyester |

0.19±0.02 |

5.50 |

9500±200 |

7 |

0.90 |

|

Copper 0.06mm |

150D Polyester |

0.19±0.02 |

12.50 |

16500±500 |

7 |

0.90 |

|

Tin Copper 0.085mm |

100D Kuraray |

0.17±0.02 |

5.00 |

16000±1000 |

5 |

2.00 |

|

Tin Copper 0.08mm |

130D Kevlar |

0.17±0.02 |

6.60 |

14500±100 |

5 |

2.00 |

|

Tin Copper 0.06mm |

130D Kevlar |

0.16±0.02 |

12.50 |

21000±500 |

3 |

2.00 |

|

Tin Copper 0.10mm |

250D Polyester |

0.23±0.02 |

4.00 |

7000±200 |

8 |

1.50 |

|

Tin Copper 0.06mm |

150D Polyester |

0.16±0.02 |

11.6 |

14000±1000 |

7 |

0.90 |

|

Tin Copper 0.085mm |

200D Kevlar |

0.19±0.02 |

5.00 |

8500±300 |

5 |

3.80 |

|

Tin Copper 0.085mm |

150D Polyester |

0.19±0.02 |

6.00 |

9500±200 |

7 |

0.90 |

|

Silver Copper 0.10mm |

250D Polyester |

0.23±0.02 |

3.90 |

7000±200 |

8 |

1.5 |

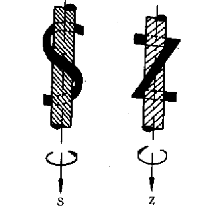

Winding direction: “Z”is bunched in a clockwise direction, “S” is the opposite direction.

Applications:

Mainly used in automobile seat heating, intelligent clothing heating, electric heating elements used in electric furnace, household electric appliances, far infrared device, cartridge heaters.

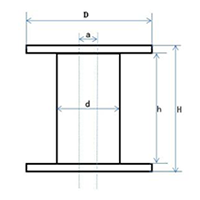

Spool Size:

P.S: Special spool can made according to customers’ requested model and size.