Chinese Professional Wire Crimp Machine - Teflon&high Temp Resistant Ourter Coating – Shielday Detail:

PTFE is known as Polytetrafluoroetylene, short for Teflon, PTFE, F4, etc.

PTFE (Teflon) is a unique high-performance coating material, which combines heat resistance, chemical inertia, excellent insulation stability and low friction, and has incommensurable advantages compared to other material:

High temperature resistant (working temperature of 250 ℃)

Low temperature resistance (-196 ℃, keep 5% elongation)

Chemical Corrosion resistance

High lubrication – lowest friction coefficient of solid materials.

Non-adhesion – does not adhere to any material.

Electrical insulation – resistance to 1500 v high voltage.

Atmospheric aging resistance: radiation resistance and low permeability.

Wire by increasing PTFE outer coated layer can improve the flexibility, temperature resistance, chemical resistance and mechanical strength, breakdown voltage. Compared with the ordinary wire, outer coating wire can be insulated , high temp resistant, also the bending life of the wire is significantly improved.

Advantages:

Insulation

High temperature / heating Resistance

Good flexibility

Stress resistance

Resistance against oils

Outer coating material, thickness of coating layer and concrete structure of inner conductive wire can be selected and combined in order to have best performance for various Applications:

Inner conductive wire material, dia:

Structure: single ,multiple stranded or not stranded / twisting direction, twisting method

1) Singel / stranded wire: Bare copper, tin-plated, silver-plated, gold-plated, nickel-plated, bare copper alloy, tin copper alloy , silver copper alloy, stainless steel etc.

Single wire Dia: 0.01~0.12mm

2) Metallized high strength yarn: above conductive wire covered aramid yarn inside which can bears the vertical tensile strength,be higher strength,more flexible, long life and temp resistance. Yarn Dia: 0.05-0.3mm

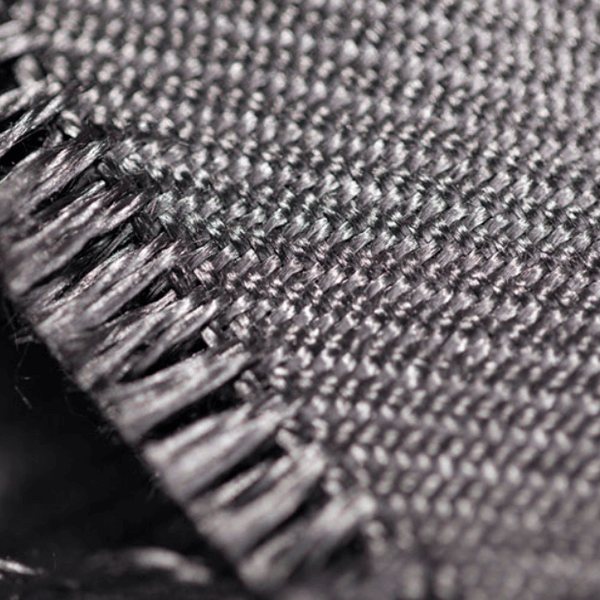

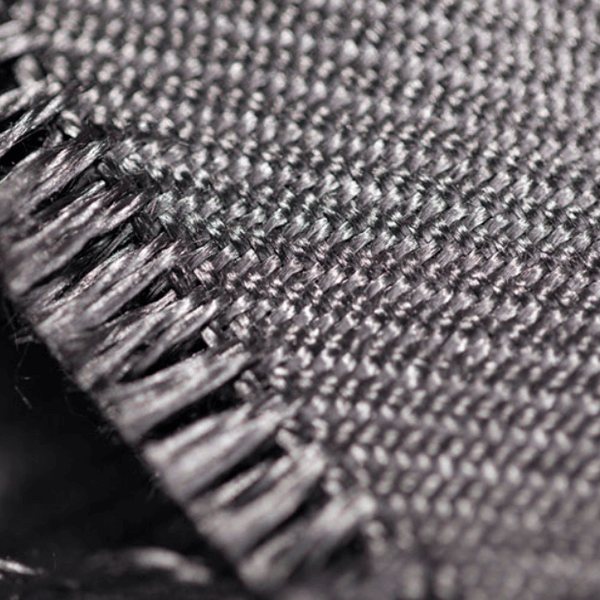

Outer insulation coating: PTFE(Teflon), HDPE(High Density Polyethylene), textile outer etc

Outer Dia: 0.5 – 5.2 mm

Coating layer thickness: ≥0.15 mm

Applications:Smart Textiles ,RFID,Medical ,Heating Etc.

Product detail pictures:

Related Product Guide:

Police: High-speed chase on Route 209 leads to one person shot | High Speed Winding & Braiding Machine

Palestinian teen: I was used as a human shield in Gaza | 4 Core Rvvp Shielded Cable

With our loaded encounter and considerate services, we have now been recognized as a trustworthy supplier for lots of worldwide consumers for Chinese Professional Wire Crimp Machine - Teflon&high Temp Resistant Ourter Coating – Shielday, The product will supply to all over the world, such as: Swiss , Cancun , Sudan , We will supply much better products with diversified designs and professional services. At the same time, welcome OEM, ODM orders, invite friends at home and abroad together common development and achieve win-win, integrity innovation, and expand business opportunities! If you have any question or need more information please feel free to contact us. We are looking forward to receiving your enquiries soon.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!

-

Cheap PriceList for Fancy Knitting Yarn - Stai...

-

Chinese Professional Jst 15pin Lvds Lvds - Fec...

-

Special Design for Copper Rod Upcast Machine - ...

-

Reliable Supplier Hospital Gown Anti Static - ...

-

Special Price for Golf Treadmill Belt - Single...

-

OEM Supply Bobbin Yarn Winder - Silver Monofil...