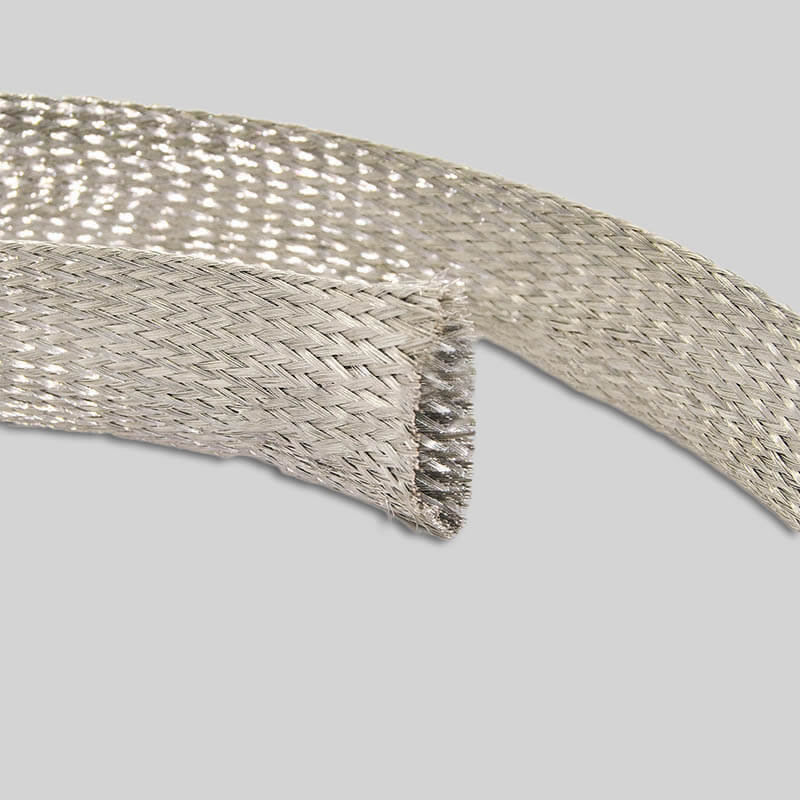

EMI shielding sleeve (SES) was generally wrapped outside the cable to avoid interference signals into the inner conductor, and reduce the loss of transmission signals so called shielding net as well. It’s flexible, wear resistant and conductive.The important feature is that it’s more suitable for operating in the narrow space because of the material’s high flexibility.It has good electrical conductivity, high strength, and can withstand various chemical corrosion resistance, high temperature resistance, radiation protection.

Wire material for sleeve available:

Copper wire – good conductivity

Tin plated copper wire – excellent conductivity and chemical resistance

Tin-copper metallized wire – flexibility, light and long working life.

Silver plated copper wire – Highest conductivity

Stainless steel wire- high temperature resistant/anti cut

Futures:

Shielding,Anti-electromagnetic interference,wire protective and anti cutting,high temperature resistance.

Applications:

high-speed rail, subway, aerospace, automotive, electrical industry and other high-tech fields, communication equipment, electronic medical equipment and military equipment, etc.

Specs:

Wire material, sleeve diameter and construction can be designed and made according to customer’s request.