Leading Manufacturer for Threads For Knitting - Teflon&high Temp Resistant Ourter Coating – Shielday Detail:

PTFE is known as Polytetrafluoroetylene, short for Teflon, PTFE, F4, etc.

PTFE (Teflon) is a unique high-performance coating material, which combines heat resistance, chemical inertia, excellent insulation stability and low friction, and has incommensurable advantages compared to other material:

High temperature resistant (working temperature of 250 ℃)

Low temperature resistance (-196 ℃, keep 5% elongation)

Chemical Corrosion resistance

High lubrication – lowest friction coefficient of solid materials.

Non-adhesion – does not adhere to any material.

Electrical insulation – resistance to 1500 v high voltage.

Atmospheric aging resistance: radiation resistance and low permeability.

Wire by increasing PTFE outer coated layer can improve the flexibility, temperature resistance, chemical resistance and mechanical strength, breakdown voltage. Compared with the ordinary wire, outer coating wire can be insulated , high temp resistant, also the bending life of the wire is significantly improved.

Advantages:

Insulation

High temperature / heating Resistance

Good flexibility

Stress resistance

Resistance against oils

Outer coating material, thickness of coating layer and concrete structure of inner conductive wire can be selected and combined in order to have best performance for various Applications:

Inner conductive wire material, dia:

Structure: single ,multiple stranded or not stranded / twisting direction, twisting method

1) Singel / stranded wire: Bare copper, tin-plated, silver-plated, gold-plated, nickel-plated, bare copper alloy, tin copper alloy , silver copper alloy, stainless steel etc.

Single wire Dia: 0.01~0.12mm

2) Metallized high strength yarn: above conductive wire covered aramid yarn inside which can bears the vertical tensile strength,be higher strength,more flexible, long life and temp resistance. Yarn Dia: 0.05-0.3mm

Outer insulation coating: PTFE(Teflon), HDPE(High Density Polyethylene), textile outer etc

Outer Dia: 0.5 – 5.2 mm

Coating layer thickness: ≥0.15 mm

Applications:Smart Textiles ,RFID,Medical ,Heating Etc.

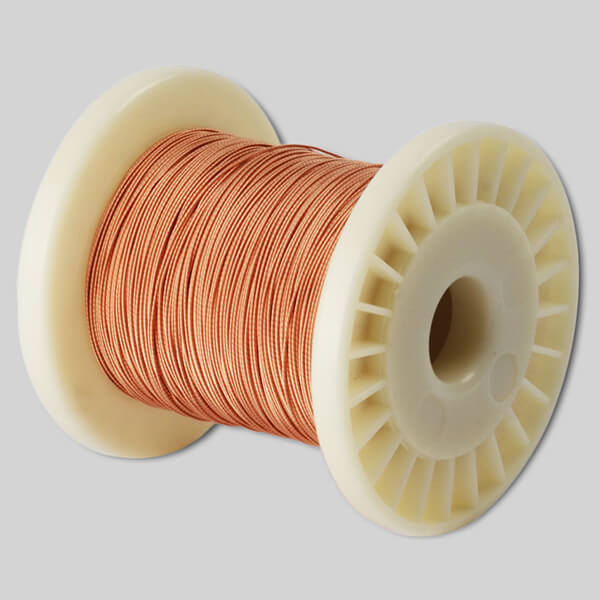

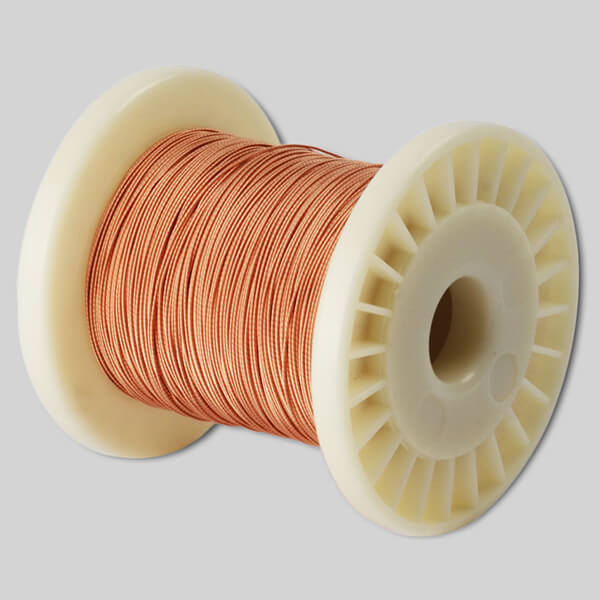

Product detail pictures:

Related Product Guide:

DPA Microphones Celebrates 25th Anniversary with Launch of First Limited Edition Kit | 4 Core Rvvp Shielded Cable

How an Australian saves lives and influences people in South Sudan | Pure Nickel Cable

We retain improving upon and perfecting our items and repair. At the same time, we perform actively to do research and progress for Leading Manufacturer for Threads For Knitting - Teflon&high Temp Resistant Ourter Coating – Shielday, The product will supply to all over the world, such as: Netherlands , Tunisia , Accra , We supply professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.

-

Factory Promotional static Seamless Belt - Sta...

-

Big discounting Hydraulic Flexible Hose - Stai...

-

Chinese Professional Fda Silicone Braided Tube ...

-

Factory Price For 7 Stranded Copper Wire - Sta...

-

High Performance Metal Hoses Braiding - Nickel...

-

Super Lowest Price Double Barbed Wire Mesh Mach...