Low MOQ for Radiation Protection Fabric For Suit - Teflon&high Temp Resistant Ourter Coating – Shielday Detail:

PTFE is known as Polytetrafluoroetylene, short for Teflon, PTFE, F4, etc.

PTFE (Teflon) is a unique high-performance coating material, which combines heat resistance, chemical inertia, excellent insulation stability and low friction, and has incommensurable advantages compared to other material:

High temperature resistant (working temperature of 250 ℃)

Low temperature resistance (-196 ℃, keep 5% elongation)

Chemical Corrosion resistance

High lubrication – lowest friction coefficient of solid materials.

Non-adhesion – does not adhere to any material.

Electrical insulation – resistance to 1500 v high voltage.

Atmospheric aging resistance: radiation resistance and low permeability.

Wire by increasing PTFE outer coated layer can improve the flexibility, temperature resistance, chemical resistance and mechanical strength, breakdown voltage. Compared with the ordinary wire, outer coating wire can be insulated , high temp resistant, also the bending life of the wire is significantly improved.

Advantages:

Insulation

High temperature / heating Resistance

Good flexibility

Stress resistance

Resistance against oils

Outer coating material, thickness of coating layer and concrete structure of inner conductive wire can be selected and combined in order to have best performance for various Applications:

Inner conductive wire material, dia:

Structure: single ,multiple stranded or not stranded / twisting direction, twisting method

1) Singel / stranded wire: Bare copper, tin-plated, silver-plated, gold-plated, nickel-plated, bare copper alloy, tin copper alloy , silver copper alloy, stainless steel etc.

Single wire Dia: 0.01~0.12mm

2) Metallized high strength yarn: above conductive wire covered aramid yarn inside which can bears the vertical tensile strength,be higher strength,more flexible, long life and temp resistance. Yarn Dia: 0.05-0.3mm

Outer insulation coating: PTFE(Teflon), HDPE(High Density Polyethylene), textile outer etc

Outer Dia: 0.5 – 5.2 mm

Coating layer thickness: ≥0.15 mm

Applications:Smart Textiles ,RFID,Medical ,Heating Etc.

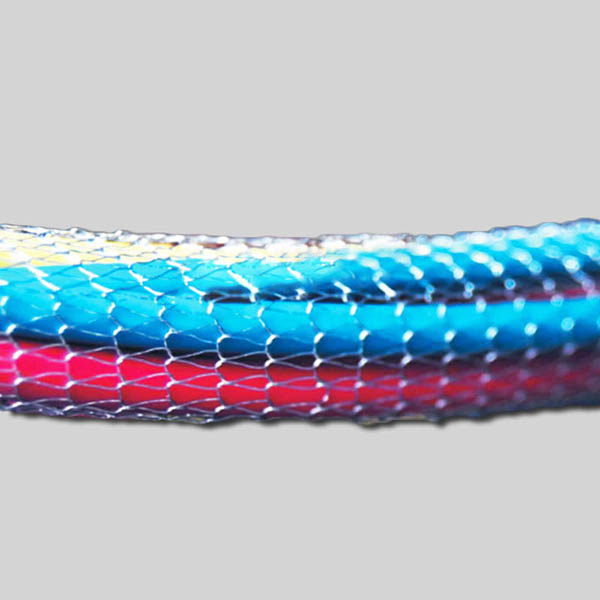

Product detail pictures:

Related Product Guide:

The Daily 202: Trump’s inexperience contributed to Comey interactions that now cloud his presidency | High Speed Winding & Braiding Machine

Fail of the Week: The Spot Welder Upgrade That Wasn’t | 4 Core Rvvp Shielded Cable

To meet the customers' over-expected gratification , we have our robust crew to offer our best over-all support which includes marketing, income, coming up with, production, excellent managing, packing, warehousing and logistics for Low MOQ for Radiation Protection Fabric For Suit - Teflon&high Temp Resistant Ourter Coating – Shielday, The product will supply to all over the world, such as: Swiss , Los Angeles , Malaysia , We taking advantage of experience workmanship, scientific administration and advanced equipment, ensure the product quality of production, we not only win the customers' faith, but also build up our brand. Today, our team is committed to innovation, and enlightenment and fusion with constant practice and outstanding wisdom and philosophy, we cater to the market demand for high-end products, to do professional products.

We have been looking for a professional and responsible supplier, and now we find it.