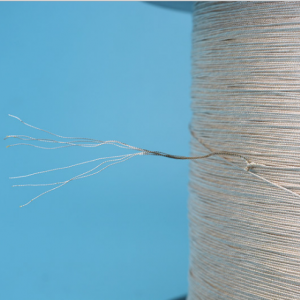

It’s silver plated copper high strength wire made by flattened silver-plated copper wire in wrapped textile filaments,due to the intermediate textile wire supporting so the conductor wire is more flexible and durable.

Wrapped textile filaments can be polyamide, aramid or other textile filaments according to your specify, it can be called metallized conductor wire or tinsel wire.

Advantages:

As the best conductor, silver has more excellent conductivity, ductility,heat conductivity and antibacterial properties than copper which is widely used in low resistance products which had strict conductivity requirement.Thin,fine and light,also its’ more flexibility and long working life than other wires, as the yarn inside can bears the vertical tensile strength.

Main specification:

Outer Dia: 0.08-0.3mm

Extruion(insulation coating) available,material can be PVC.Teflon etc according to your specify.

Stranding available.

All wire can be designed and customized according to customers’ request of performance, technical parameters, outer diameter etc.

The advantages Compared to conventional conductor wires :

1. Extremely Low resistance and excellent conductivity;

2. More flexibility and long working life;

3. Good corrosion resistance and high reliability;

4. High tensile strength, durable.

5. Good solderability.

Conductor materials available:

Silver-plated, tin-plated,, gold-plated,nickel-plated, bare Silver alloy, tin copper alloy , silver copper alloy etc. All wire can be designed and customized according to customers’ request of performance, technical parameters, outer diameter etc.

Regular Specification Data:

|

Outer Conductor |

Textile Inner Core |

Diameter mm |

Conductivity ≤Ω/m |

Weight m/KG |

Elongation≥% |

Strength ≥KG |

|

Copper 0.08mm |

250D Poyester |

0.20±0.02 |

6.50 |

9000±150 |

8 |

1.50 |

|

Copper 0.10mm |

250D Polyester |

0.23±0.02 |

3.90 |

7000±200 |

10 |

1.50 |

|

Copper 0.05mm |

50D Kuraray |

0.10±0.02 |

12.30 |

28000±1500 |

3 |

0.70 |

|

Copper 0.1mm |

200D Dinima |

0.22±0.02 |

4.00 |

7000±200 |

5 |

4.00 |

|

Copper 0.1mm |

250D Polyester |

1*2/0.28 |

2.00 |

5300±500 |

8 |

1.50 |

|

Copper 0.1mm |

200D Kevlar |

0.22±0.02 |

4.00 |

7300±200 |

5 |

3.80 |

|

Copper 0.05mm |

50D Polyester |

1*2/0.13 |

8.50 |

28000±1500 |

5 |

0.35 |

|

Copper 0.05mm |

70D Polyester |

0.11±0.02 |

12.50 |

21500±1500 |

5 |

0.45 |

|

Copper 0.55mm |

70D Polyester |

0.12±0.02 |

12.30 |

21000±1500 |

5 |

0.45 |

|

Copper 0.10mm |

Cotton 42S/2 |

0.27±0.03 |

4.20 |

6300±200 |

7 |

1.10 |

|

Copper 0.09mm |

150D Polyester |

0.19±0.02 |

5.50 |

9500±200 |

7 |

0.90 |

|

Copper 0.06mm |

150D Polyester |

0.19±0.02 |

12.50 |

16500±500 |

7 |

0.90 |

|

Tin Copper 0.085mm |

100D Kuraray |

0.17±0.02 |

5.00 |

16000±1000 |

5 |

2.00 |

|

Tin Copper 0.08mm |

130D Kevlar |

0.17±0.02 |

6.60 |

14500±100 |

5 |

2.00 |

|

Tin Copper 0.06mm |

130D Kevlar |

0.16±0.02 |

12.50 |

21000±500 |

3 |

2.00 |

|

Tin Copper 0.10mm |

250D Polyester |

0.23±0.02 |

4.00 |

7000±200 |

8 |

1.50 |

|

Tin Copper 0.06mm |

150D Polyester |

0.16±0.02 |

11.6 |

14000±1000 |

7 |

0.90 |

|

Tin Copper 0.085mm |

200D Kevlar |

0.19±0.02 |

5.00 |

8500±300 |

5 |

3.80 |

|

Tin Copper 0.085mm |

150D Polyester |

0.19±0.02 |

6.00 |

9500±200 |

7 |

0.90 |

|

Silver Copper 0.10mm |

250D Polyester |

0.23±0.02 |

3.90 |

7000±200 |

8 |

1.5 |

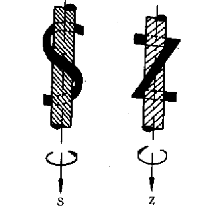

Winding direction: “Z”is bunched in a clockwise direction, “S”is the opposite direction.

Applications:

shielding,conductive,anti bacterial, anti static textile, RFID conductor,military,precision instruments, medical equipment (surgery grade conductor),charging pile wires, robot wire, aerospace wire & cable,ship/cabin wire & cable, high-end headset wire, cell phone speaker wire, towline cable, railway track cable, as well as the field of industrial cable and special wire and cable.

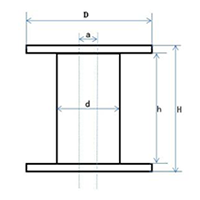

Spool Size:

P.S: Special spool can made according to customers’ requested model and size.