New Fashion Design for Bunching Machine - High Density Polyethylene (HDPE) – Shielday Detail:

High density polyethylene (HDPE) softening point for 125 ~ 135 ℃,

working temperature 100 ℃;

Material features:

Heat & cold resistance, good abrasion resistance, high tensile strength, electrical insulation, good chemical stability, chemical corrosion resistance; low water absorption and permeability.

Wire by increasing HDPE outer coated layer can improve the flexibility, temperature resistance, chemical resistance and mechanical strength, breakdown voltage. Compared with the ordinary wire, outer coating wire can be insulated , high temp resistant, also the bending life of the wire is significantly improved.

Advantages:

Insulation

High temperature / heating Resistance

Good flexibility

Stress resistance

Resistance against oils

Outer coating material, thickness of coating layer and concrete structure of inner conductive wire can be selected and combined in order to have best performance for various applications:

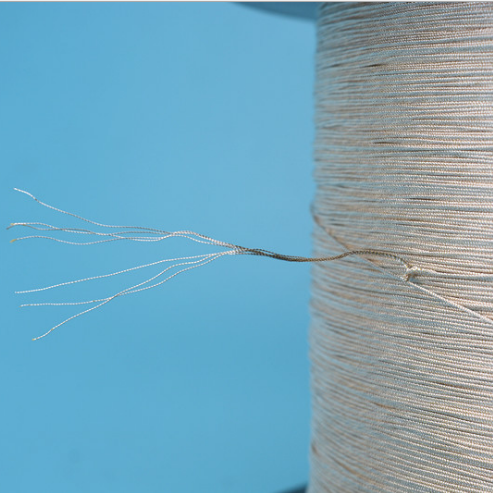

Inner conductive wire material, dia:

Structure: single ,multiple stranded or not stranded / twisting direction, twisting method

1) Singel / stranded wire: Bare copper, tin-plated, silver-plated, gold-plated, nickel-plated, bare copper alloy, tin copper alloy , silver copper alloy, stainless steel etc.

Single wire Dia: 0.01~0.12mm

2) Metallized high strength yarn: above conductive wire covered aramid yarn inside which can bears the vertical tensile strength,be higher strength,more flexible, long life and temp resistance. Yarn Dia: 0.05-0.3mm

Outer insulation coating: PTFE(Teflon), HDPE(High Density Polyethylene), textile outer etc

Outer Dia: 0.5 – 5.2 mm

Coating layer thickness: ≥0.15 mm

Applications:Smart Textiles ,RFID,Medical ,Heating Etc.

Product detail pictures:

Related Product Guide:

Roku Stock Downgraded: What You Need to Know — The Motley Fool | High Speed Winding & Braiding Machine

Teardown Shows Why Innovative Designs Sometimes Fail | Stainless Steel Braided Sleeve

It can be our duty to satisfy your preferences and successfully serve you. Your pleasure is our best reward. We have been looking forward to the go to for joint expansion for New Fashion Design for Bunching Machine - High Density Polyethylene (HDPE) – Shielday, The product will supply to all over the world, such as: Montreal , Swaziland , panama , Our tenet is "integrity first, quality best". Now we have confidence in providing you with excellent service and ideal merchandise. We sincerely hope we can establish win-win business cooperation with you in the future!

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!