OEM Manufacturer Polyester Wadding - Electric and Electronic Wire Extrusion Line – Shielday Detail:

Electrical and Electronic Wires Extrusion Line

| Model | XD-WEL-30 | XD-WEL-40 | XD-WEL-50 | XD-WEL-60 | XD-WEL-70 |

| Pay off type | Active type | Dual-shaft type | Dual-shaft /Big-Shaft/Shaft free | Dual-shaft /Big-Shaft/Shaft free | Dual-shaft /Big-Shaft/Shaft free |

| Pay off Dia (mm) | 300/400/500 | 400/500/630 | 500/630/800/1250 | 500/630/800/1250 | 500/630/800/1250 |

| Screw dia (mm) | 30/40/50 | 60/65/70 | 80/90 | 80/90 | 80/90 |

| Screw dia proportion | 25:1 | 25:1 | 25:1 | 25:1 | 25:1 |

| Bold speed (rpm) | 10-110 | 10-100 | 10-80 | 10-80 | 10-80 |

| Output (kg/h) | 25-80 | 100-120-140 | 250-300 | 250-300 | 250-300 |

| Feeding speed (kg/h) | 250 | 250 | 300 | 300 | 300 |

| M/E POWER | 5.5/7.5/11 | 18.5/22 | 30-37 | 30-37 | 30-37 |

| Wire dia (mm) | 0.6/6.0 | 2.0-12.0 | 4.0-20.0 | 4.0-20.0 | 4.0-20.0 |

| Cooling systerm | Fold away V shape or single(dual)layer U shape | ||||

| Max accumulation length(m) | 250 | 200 | 150 | 150 | 150 |

| Take-up ratio (kw) | 2.2 | 3.7-5.5 | 5.5 | 5.5 | 5.5 |

| Linear speed(m/min) | 0-600 | 0-400 | 0-400 | 0-400 | 0-400 |

| Take-up type | Double axis equipment/axis equipment | Dual-shaft /Big-Shaft/Shaft free | Dual-shaft /Big-Shaft/Shaft free | Dual-shaft /Big-Shaft/Shaft free | |

| Take-up reel dia (mm) | 300/400/500 | 400/500/600 | 500/630/800/1250 | 500/630/800/1250 | 500/630/800/1250 |

| Take-up power | 2.2 | 2.2 | 3.7/5.5 | 3.7/5.5 | 3.7/5.5 |

Consisting Components:

1,double-shaft pay-off rack

2,straightener platform

3,main extruder

4,automatic dryer and hopper

5,electric apparatus main control cabinet

6,Double layer movable trough

7,laser diameter gauge or Digital Diameter controller

8,high speed printing machine

9,double-wheels capstan

10,Meter counter

11,horizontal type wire-accumulator

12,power frequency sparker

13,double-shaft take-up machine

Applications:

Suitable for single-layer, dual layer and three layer extrusion operations in making wires and cables with such insulation materials as PVC, LDPE, XLPE,LSHF, Nylon and TPU, TPE.

Product detail pictures:

Related Product Guide:

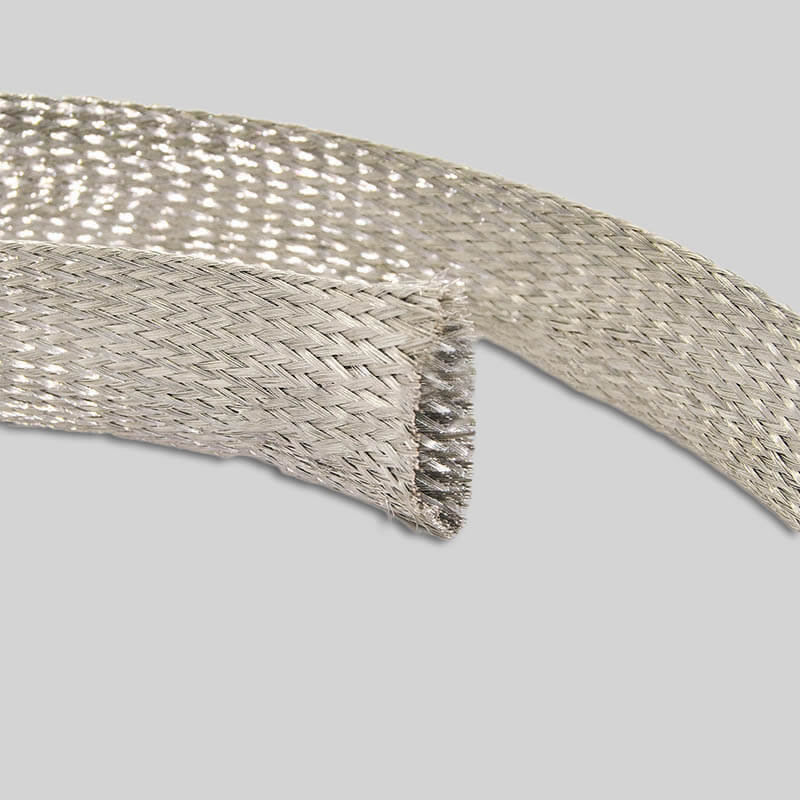

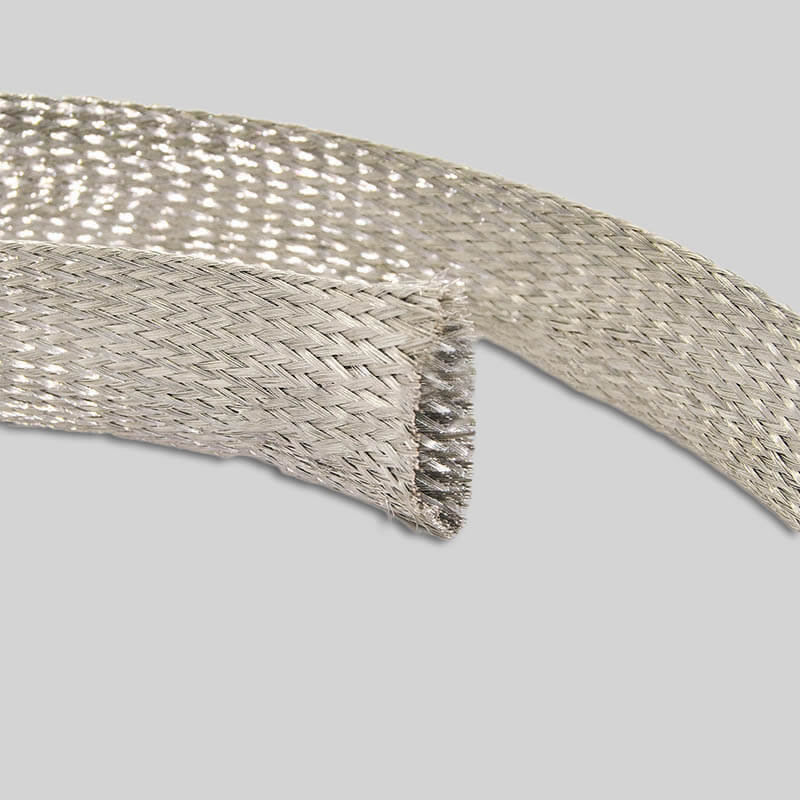

Mark Blazis: State’s deer hunting season is winding down – News – telegram.com | Stainless Steel Braided Sleeve

BTPA Unveils Solderless Patch Cable Kit | High Speed Winding & Braiding Machine

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" and the theory of "quality the basic, trust the first and management the advanced" for OEM Manufacturer Polyester Wadding - Electric and Electronic Wire Extrusion Line – Shielday, The product will supply to all over the world, such as: Cannes , Mauritania , South Africa , We believe that good business relationships will lead to mutual benefits and improvement for both parties. We now have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!

-

Factory Supply Dog Training Collars - Stainles...

-

China Gold Supplier for Building Electric Cable...

-

Low MOQ for Pvc Tarpaulin Factory - Fecral Hig...

-

Rapid Delivery for Metal Tapes - Stainless Ste...

-

New Arrival China Esd Stripe Fabrics - Stainle...

-

Special Design for Hair Braiding Machine - Sta...