Popular Design for Paper Phenolic Rod - High Density Polyethylene (HDPE) – Shielday Detail:

High density polyethylene (HDPE) softening point for 125 ~ 135 ℃,

working temperature 100 ℃;

Material features:

Heat & cold resistance, good abrasion resistance, high tensile strength, electrical insulation, good chemical stability, chemical corrosion resistance; low water absorption and permeability.

Wire by increasing HDPE outer coated layer can improve the flexibility, temperature resistance, chemical resistance and mechanical strength, breakdown voltage. Compared with the ordinary wire, outer coating wire can be insulated , high temp resistant, also the bending life of the wire is significantly improved.

Advantages:

Insulation

High temperature / heating Resistance

Good flexibility

Stress resistance

Resistance against oils

Outer coating material, thickness of coating layer and concrete structure of inner conductive wire can be selected and combined in order to have best performance for various applications:

Inner conductive wire material, dia:

Structure: single ,multiple stranded or not stranded / twisting direction, twisting method

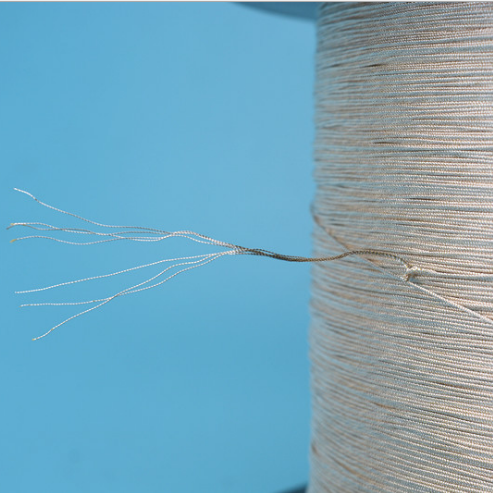

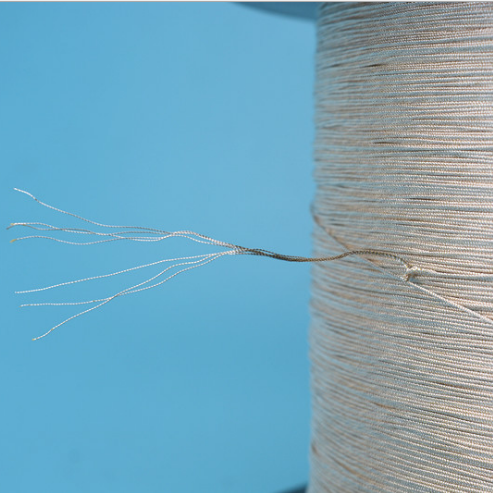

1) Singel / stranded wire: Bare copper, tin-plated, silver-plated, gold-plated, nickel-plated, bare copper alloy, tin copper alloy , silver copper alloy, stainless steel etc.

Single wire Dia: 0.01~0.12mm

2) Metallized high strength yarn: above conductive wire covered aramid yarn inside which can bears the vertical tensile strength,be higher strength,more flexible, long life and temp resistance. Yarn Dia: 0.05-0.3mm

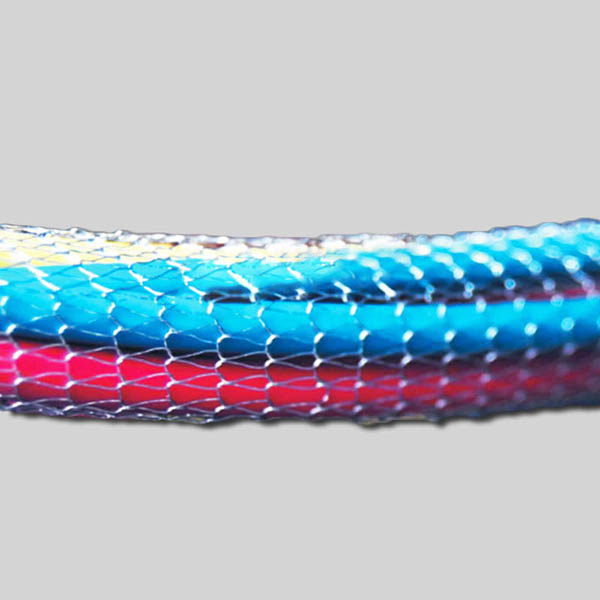

Outer insulation coating: PTFE(Teflon), HDPE(High Density Polyethylene), textile outer etc

Outer Dia: 0.5 – 5.2 mm

Coating layer thickness: ≥0.15 mm

Applications:Smart Textiles ,RFID,Medical ,Heating Etc.

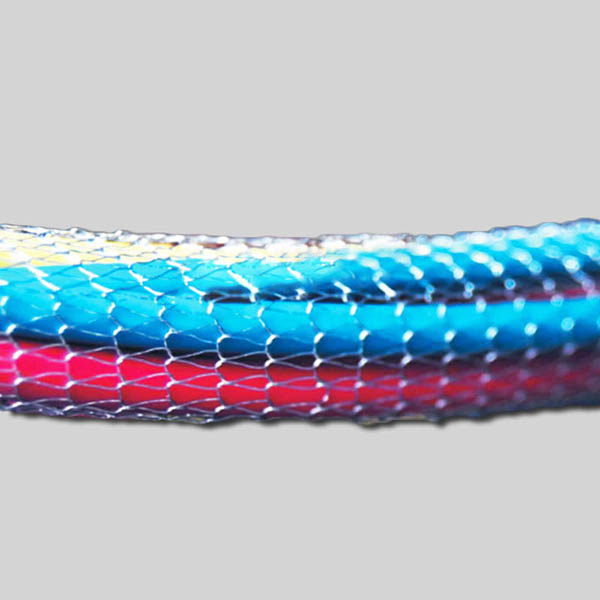

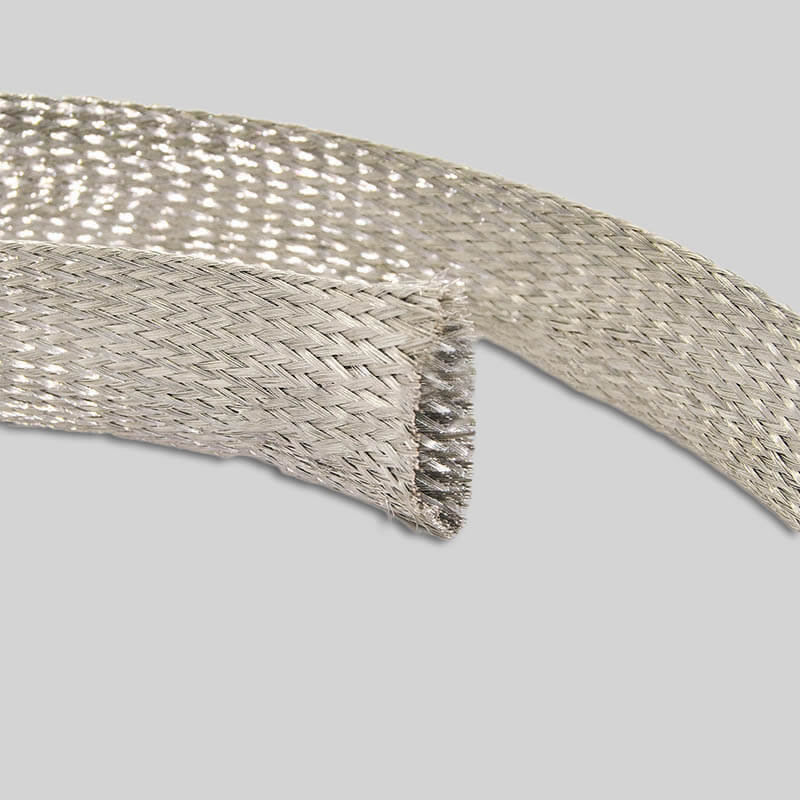

Product detail pictures:

Related Product Guide:

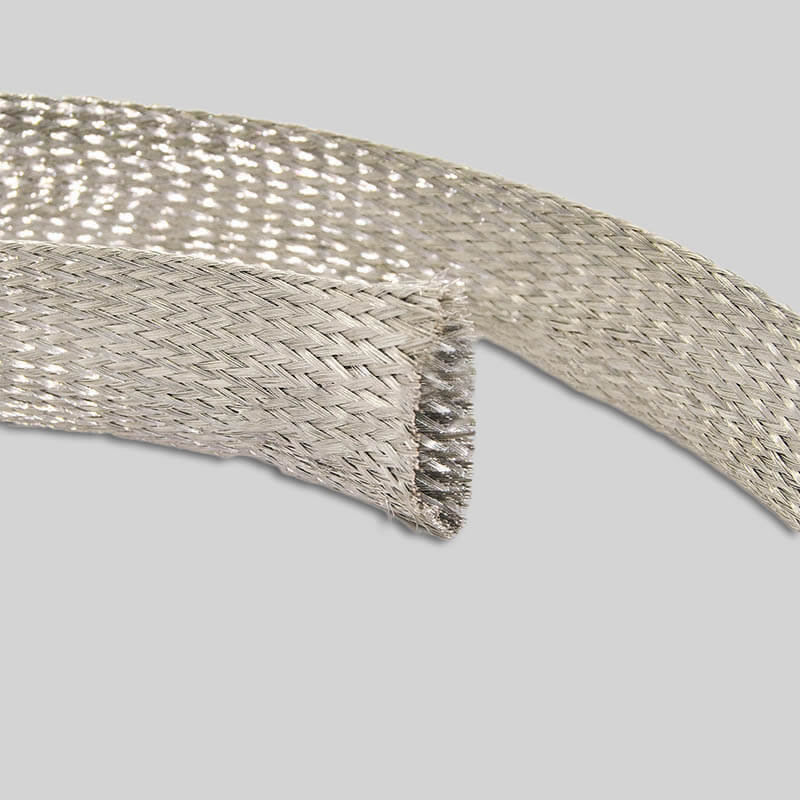

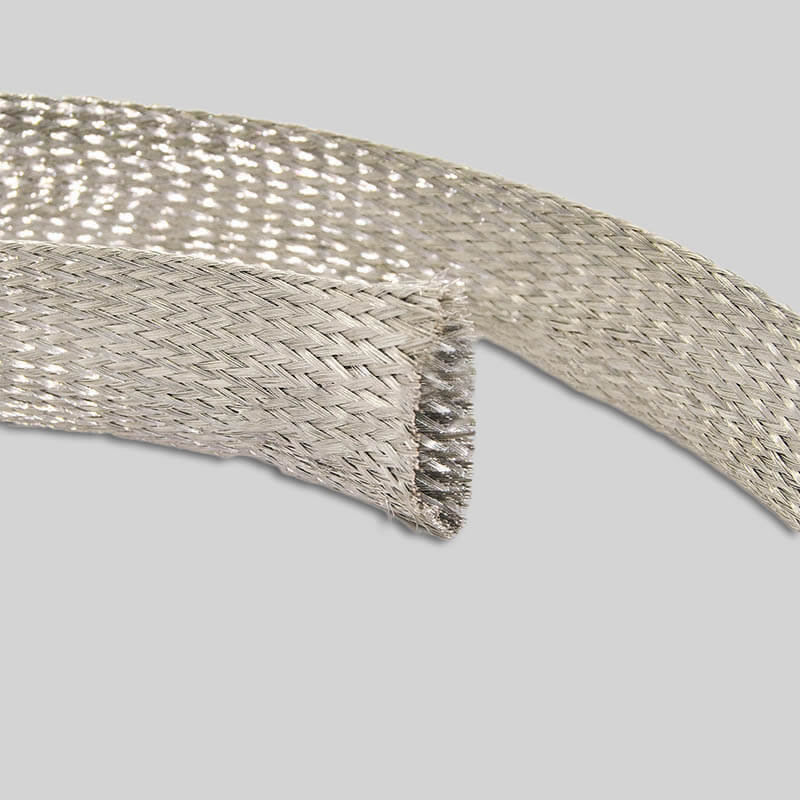

Powered Subwoofer Connection to New Receiver | Stainless Steel Braided Sleeve

Things to Do on the Lower East Side This Month | Stainless Steel Braided Sleeve

Our enterprise insists all along the standard policy of "product high-quality is base of business survival; client satisfaction could be the staring point and ending of an business; persistent improvement is eternal pursuit of staff" as well as consistent purpose of "reputation first, client first" for Popular Design for Paper Phenolic Rod - High Density Polyethylene (HDPE) – Shielday, The product will supply to all over the world, such as: Jeddah , Chile , Lisbon , "Make the women more attractive "is our sales philosophy. "Being customers' trusted and preferred brand supplier" is the goal of our company. We are strict with every part of our work. We sincerely welcome friends to negotiate business and start cooperation. We hope to join hands with friends in different industries to create a brilliant future.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.

-

OEM Manufacturer Emi Sleeve Shielding - Silver...

-

OEM Factory for Red Silicone Rubber Cable - Me...

-

Newly Arrival Copper Wire Granulator Machine - ...

-

Professional China Custom Cashmere Yarn - Tin...

-

18 Years Factory Fluorine Plastic High-Temperat...

-

Super Lowest Price Cat5e Network Cable - Coppe...